This article was first published on LinkedIn network and was written by John Soldatos jointly with Mauro Isaja both members of FAR-EDGE consortium, addresses the Functional Viewpoint and the Structural Viewpoint of the FAR-EDGE Reference Architecture (RA) and is also available here.

In a previous post we introduced the H2020 FAR-EDGE project and its goals. In this article, we outline the main elements of the FAR-EDGE Reference Architecture (RA), which is the conceptual framework that is driving the implementation of the FAR-EDGE factory automation platform. This RA is aimed as a vehicle for communication and collaboration between relevant stakeholders, including both the FAR-EDGE team and third-parties that would like to engage in the project’s activities as users or contributors. Therefore, the FAR-EDGE RA is presented based on constructs and formalisms that are compliant to ISO/IEC/IEEE 42010:2011. It’s also important that the main elements of the architecture map to constructs, concepts and layers of other Reference Architectures for the Industrial Internet, including standards the RA of the OpenFog Consortium, the RAMI 4.0 (Reference Architecture Model Industry 4.0) architecture model, as well as the RA of the Industrial Internet Consortium (i.e. IICRA).

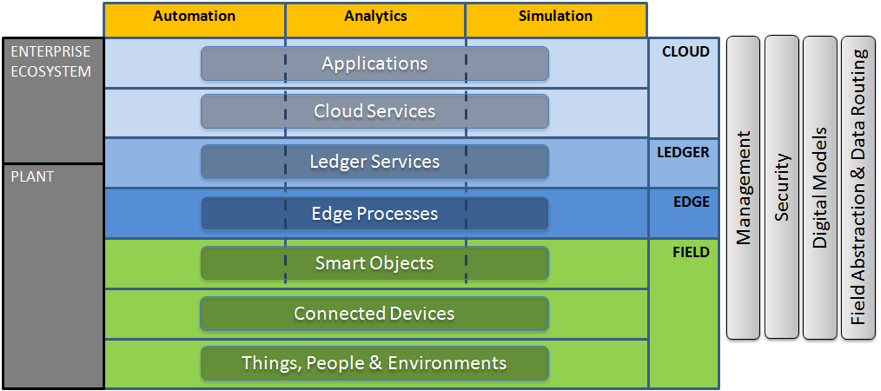

An overall view of the architecture is provided in the following figure. The RA can be seen from two different (complementary) viewpoints, namely a functional viewpoint and a structural viewpoint. In particular, the top part of the figure describes the main functionalities of the RA in the form of functional domains (i.e. Automation, Analytics, Simulation), while at the right hand-side a tiered structured (Cloud, Ledger, Edge, Field Tiers) is evident.

Functional Viewpoint

The functional viewpoint of the FAR-EDGE RA comprises three high-level functional domains (Automation, Analytics and Simulation) and four cross-cutting functions (Management, Security, Digital Models and Field Abstraction & Data Routing). The concept of domains and cross-cutting functionalities is similar to those used in the Industrial Internet Reference Architecture (IIRA).

The functional domains represent the main functionalities to be provided by FAR-EDGE and include:

- The Automation Domain, which supports automated control and automated configuration of physical production processes. Automated configuration is the enabler of plug-and-play factory equipment (i.e. plug-and-produce), which in turn is a key technology for mass-customization, as it allows faster and less expensive adjustments of the production process to cope with a very dynamic market demand. The Automation domain requires a bidirectional monitoring/control communication channel with the Field, typically with low bandwidth but very strict timing requirements (tight control loop). In some advanced scenarios, Automation is controlled – to some extent – by the results of Analytics and/or Simulation.

- The Analytics Domain, which supports gathering and processing Field data towards a better understanding of production processes – i.e., a factory-focused business intelligence. This requires a high-bandwidth field communication channel to handle large data volumes, even though channel latency in analytic functionalities are less critical than automation ones. An interaction between the Analytics and Automation domains can be configured to enable one to reinforce the other. For example, an automation workflow might change based on changes detected in the controlled process – e.g., a process drift caused by the progressive wear of machinery or by the quality of assembly components being lower than usual. Data analytics functionalities can be also combined with simulation domain functions in order to update the parameters of a digital model.

- The Simulation Domain, which simulates the behaviour of physical production processes for the purpose of optimization or of testing what/if scenarios at minimal cost and risk and without any impact of regular shop activities. The simulation requires digital models of plants and processes to be synchronized with the real world objects they represent. For instance, the model of a machine assumes a given value of electric power/energy consumption, but the actual values will diverge as the real machine wears down. To detect this gap and correct the model accordingly, raw data from the Field (direct) or complex analysis algorithms (from Analytics) can be used.

Crosscutting Functions complement vertical functional domains through addressing common concerns. They are used by various Functional Domains & Tiers. They include:

- Management: Low-level functions for monitoring and commissioning/decommissioning of individual system modules – i.e., factory equipment and IT components that expose a management interface.

- Security: Functions securing the system against the unruly behaviour of its user and of connected systems. These include digital identity management and authentication, access control policy management and enforcement, communication and data encryption.

- Digital Models: Functions for the management of digital models and their synchronization with the real-world entities they represent. Digital modes are a shared asset, as they may be used as the basis for automated configuration, simulation and field abstraction – e.g., semantic interoperability of heterogeneous field systems.

- Field Abstraction & Data Routing: Functions that ensure the connectivity of business logic (FAR-EDGE RA Functional Domains) to the Field, abstracting away the technical details – like device discovery and communication protocols. Data routing refers to the capability of establishing direct producer-consumer channels on demand, optimized for unidirectional massive data streaming – e.g., for feeding Analytics.

Structural Viewpoint

The FAR-EDGE RA specifies the structure of a factory automation system based on scopes and tiers. Scopes define a coarse mapping of system elements to either the factory (Plant Scope) or the broader world of corporate IT (Enterprise Ecosystem Scope). Plant Scope elements include are machinery, Field devices, workstations, SCADA and MES systems, and any software running in the factory data centre. On the other hand, Enterprise Ecosystem Scope comprises systems like ERP (Enterprise Resource Planning) and PLM (Product Lifecycle Management).

Furthermore, FAR-EDGE compliant systems are structured based on the following tiers:

- The Field Tier, which is the bottom layer of the FAR-EDGE RA and is populated by Edge Nodes (EN) i.e. any kind of device that is connected to the digital world on one side and to the real world to the other. ENs can have embedded intelligence (e.g., a smart machine) or not (e.g., an IoT sensor or actuator). The Field Tier is in Plant Scope.

- The Edge Tier, which hosts those parts of Functional Domains and XC Functions that can leverage the edge computing model – i.e., software designed to run on multiple, distributed computing nodes placed close to the field, which may include resource constrained nodes. The Edge Tier is populated by Edge Gateways (EG) i.e. computing devices that act as a digital world gateway to the real world of the Field. Strategically positioned close to physical systems, the EG can execute Edge Processes i.e. time- and bandwidth-critical functionality such as the real-time analysis of a huge volume of live data that is streamed from a nearby Field source. The Edge Tier is also in Plant Scope, located above the Field Tier and below the Cloud Tier.

- The Ledger Tier, which is an abstraction without any specific physical deployment The Ledge Tier comprises Ledger Services, which implement decentralized business logic as smart contracts on top of a distributed ledger (i.e. blockchain based) infrastructure. Hence, Ledger Services are transaction-oriented: each service call that needs to modify the shared state of a system must be evaluated and approved by Peer Nodes before taking effect. They are used to Ledger Services implement the part of Functional Domains and/or XC Functions that enable the edge computing model, through providing support for their Edge Service counterpart. Smart contracts are therefore used to regulate the behaviour of the Automation and Distributed Analytics functional domains, through orchestrating data processing functions or machine participating in automation workflows. The Ledger Tier lays across the Plant and the Enterprise Ecosystem Scopes, as it can provide support to any Tier.

- The Cloud Tier, which is the simplest and more “traditional” one. It is populated by Cloud Servers (CS), which support the execution of the business logic of Functional Domains and XC Functions, notably business logic that must have the widest of scopes over production processes. This includes planning, monitoring and management of entire factories, enterprises and supply chains (e.g., MES, ERP and SCM systems). Subsequently, the Cloud Tier is in Enterprise Ecosystem scope.

Conclusions, Outlook and Your Feedback

The FAR-EDGE RA provides the means for structuring factory automation systems based on edge computing and distributed ledger technologies at a high-level. In the H2020 FAR-EDGE deliverable D2.4, we provide more details on the functional and structural viewpoints of FAR-EDGE compliant systems, while at the same time providing their mapping to concepts of RAMI4.0 and IICRA. Furthermore, in this document, we also provide an implementation viewpoint, through outlining a pool of implementation technologies that can be used to implement the various functional domains and cross-cutting functions of the FAR-EDGE RA, fully in-line with the presented tiered structure. In a coming post, we will provide concrete examples on how this reference architecture is used to create pragmatic factory automation systems based on blockchains and the edge computing paradigms. We also plan to gradually release community versions of our implementation libraries.

To stay informed about FAR-EDGE developments, please visit the project’s website at: http://www.faredge.eu or subscribe to FAR-EDGE’s LinkedIN group at: https://www.linkedin.com/groups/12026611.

You can also request access to the full text of the D2.4 deliverable through sending me a LinkedIn message, listing your name, affiliation, e-mail and purpose for which you are requesting the document.

Acknowledgement: This post was written jointly with Mauro Isaja, who is the main contributor to the FAR-EDGE RA. We acknowledge help and contribution from all members of the H2020 FAR-EDGE consortium.